Lab Automation and Data-Driven Materials Science

Our group develops and integrates automated experimentation platforms, open-source hardware, and data-driven workflows to accelerate research in soft materials and colloid science.

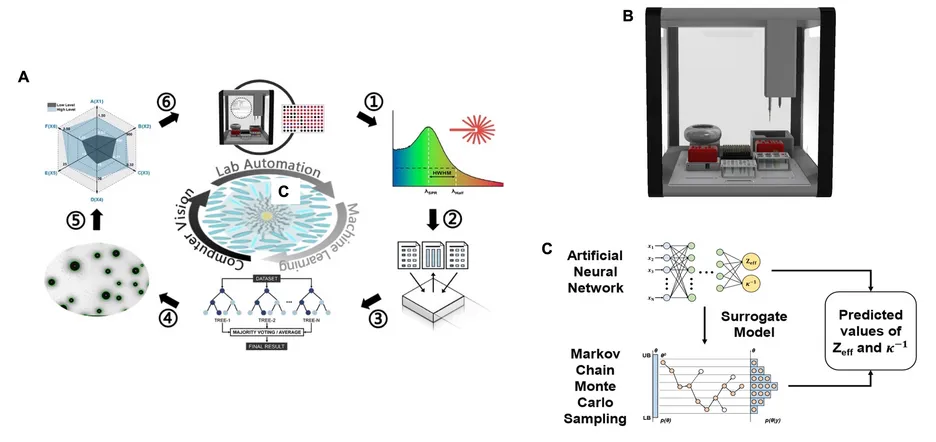

A central goal is to enable high-throughput, reproducible experimentation. We have constructed a modular robotic workstation based on the OT-2 liquid handling robot. This platform automates synthetic workflows and downstream characterisation, including temperature-controlled reactions, mixing, and separation via a smart centrifuge with positional control. The custom-built centrifuge, compatible with various deck configurations, ensures reliable sample alignment and operation, addressing a key limitation in existing open-source automation hardware.

To support these experimental advances, we apply statistical tools such as Design of Experiments (DoE) and machine learning models to extract insight from complex datasets. In a recent study, we optimised the solubility of functionalised colloidal building blocks in liquid crystal matrices using a closed-loop workflow that included DoE, UV-vis spectroscopy, and random forest classification models. We further developed a generalised additive model for predicting spectral features and applied computer vision analysis to quantify structural transitions.

In a related study, we demonstrated a workflow combining small-angle X-ray scattering (SAXS), Monte Carlo simulations, and artificial neural networks (ANNs) to infer colloidal interaction parameters. This hybrid approach enables accurate and efficient prediction of key parameters, such as Debye length and effective charge, even when analytical fitting fails. Incorporating Markov chain Monte Carlo (MCMC) sampling with an ANN surrogate model further provides confidence intervals and correlation data for parameter estimates.