REGULUS-ISAR: Innovation network for material utilization of recovered wood on a regional scale (ISAR)

Subproject: Modeling of future recovered wood supply and utilization, dynamic recovered wood system simulation and evaluation.

The transformation from a fossil-based to a bio-based economy suggests an increased use of wood with new market players. Besides long-term carbon sequestration (climate protection), resource efficiency is one of the goals in the wood sector. For the development of a circular wood-based bioeconomy, the development of new reuse and recycling processes in terms of cascade utilization is essential. Up to now, recovered wood is mainly used for energy generation, so that the C-binding potential in recovered wood as well as the substitution potential compared to fossil raw materials and primary wood has not been utilized so far. However, stakeholders currently have little incentive to initiate high-quality material recycling, due to existing investments and general reservations towards recovered wood.

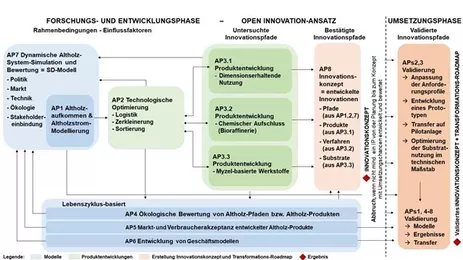

Therefore, the aim of the joint project is the development of an innovation concept for the circular-optimized material use of recovered wood (research phase) in an open innovation approach and its validation in real laboratories (implementation phase) in Bavaria. These results are used to identify optimization potentials and measures for an implementation of the concept in practice. At the same, time existing challenges and opportunities are to be identified and innovation paths are to be developed that are technically and economically feasible as well as ecologically and socially suitable. Based on a circular cascade model, three innovation paths will be pursued:

- Dimension-preserving solid wood utilization (sorting and preparation of recovered wood to the development of a product)

- Development and optimization of chemical pulping processes for recovered wood as a raw material in biorefineries

- Potentials of recovered wood as substrate for fungal mycelium-based materials and development of corresponding products

Duration: 02/2023 – 01/2026

People:

AP1, AP4 und AP7:

Chair of Wood Science: Mika Hayashi, Gabriele Weber-Blaschke

The project part of the working group Resource Flow Management deals with the work packages AP1, AP4 and AP7. In AP1, the future recovered wood flow is modeled and validated. Further on, in AP4, the aim is to conduct a prospective life cycle assessment of selected recovered wood innovation paths and recovered wood products.

Work package 7 focuses on identifying the main factors influencing recovered wood flows and analyzing interactions in order to create a dynamic recovered wood system simulation (dRWSS) model, to develop scenarios and, to validate and evaluate them using real data.

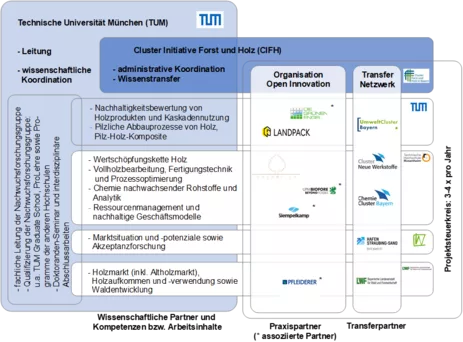

Other project partners

- Cluster Initiative Forest and Wood in Bavaria gGmbH (Stefan Torno)

- Admin. Coordination and knowledge transfer partners

=> AP8 - Technical University of Munich (Chair of Fungal Biotechnology in Wood Science, Philipp Benz, Tanja Karl)

=> AP3.2 und AP3.3 - Rosenheim Technical University of Applied Sciences (Faculty of Management and Engineering, Sandra Krommes; Faculty of Chemical Technology and Economics, Dominik Pentlehner; Faculty of Wood Technology and Construction, Matthias Zscheile; Centre for Bio-based Materials, Veronika Auer)

=> AP2, AP3.1, AP3.2, and AP6 - Weihenstephan-Triesdorf University of Applied Sciences (Chair of Marketing and Management of Renewable Resources, Klaus Menrad)

=> AP5 - The Bavarian State Institute of Forestry (Department of Forestry Technology, Business Management and Wood; Johannes Metsch)

=> AP1 - Franz Obermeier GmbH (practice partner)

- Landpack GmbH (practice partner)

Homepage of the REGULUS Initiative with all projects: REGULUS

Granted by: